Hotline:13916750352

Notice:

Currently, commercial high power LED lights (including LED street light, industrial lights, tunnel light and so on)are mostly integrally-designed, which means all components are sealed in a housing to keep them waterproof and dustproof. The short of the design is obviously, how to repair it if some of components fail in its lifetime? What will we do after its lifetime? How to upgrade it when LED’s efficacy is increasing? The short makes the LED lights not competitive to those lights by HPS or HID bulb.

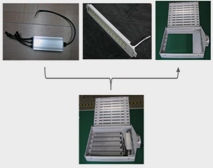

Great different from the LED light in integral design mentioned above, the LED light in modular design is made of one or several LED modules (so called LED light engines by Zhaga), one driver module and one housing. The LED light engines have built-in optics designed for desired light distribution and built-in heat sink, all the LED light engines and driver module are IP67 designed. Therefore, the housing serves only for holding the modules, installation and decoration. This unique structure makes the luminaire flexible, easy maintenance in fields and upgradeable in future. The design is in a concept compared to HPS light:

LED light =LED light engines + LED diver module + housing

Where LED light engine and LED driver module can be replaced in field without tools or with simple tools when they fail.

The modular design and imtegral design

Integral street light

modular street light

Copyright © 2011-2023 Shanghai LightEngin Technology Co., Ltd. 沪ICP备11042523号-1